Sprayed concrete

Order shipped within 7 days

Harmony Sprayed Concrete is a two-component mortar comprised of resin, cement, admixtures and special fillers, which is applied using a spray gun.

Harmony Sprayed Concrete is used for the production of decorative floors, whether in new structures or in renovation projects. It may be applied, with or without a pattern, on a wide variety of base surfaces (concrete, mortar, bitumen, etc.).

Color

Change color

Please note that the accuracy of a color on a screen is in no way reliable and depends on the calibration of the screen and its resolution. Each computer or phone screen does not have the same calibration and does not give a precise shade.

Packaging

Description

Description

Harmony Sprayed Concrete is a two-component mortar comprised of resin, cement, admixtures and special fillers, which is applied using a spray gun.

Harmony Sprayed Concrete is used for the production of decorative floors, whether in new structures or in renovation projects. It may be applied, with or without a pattern, on a wide variety of base surfaces (concrete, mortar, bitumen, asphalt, etc.).

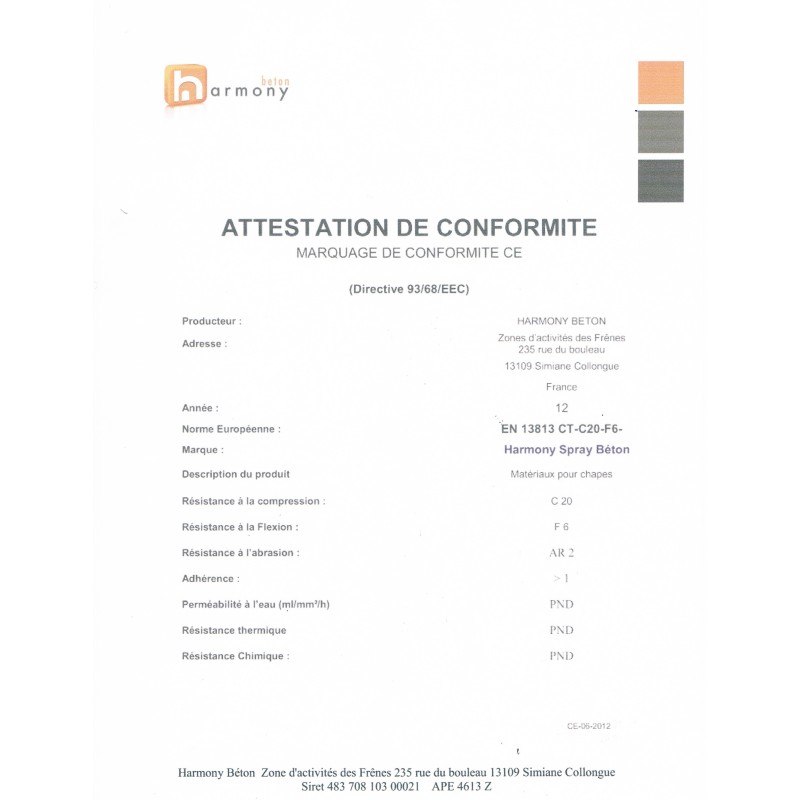

Characteristics

Type: fine two-component mortar

Colours: 8

Packaging: 25kg +5 l resin.

Particle size: 0/0,4 mm

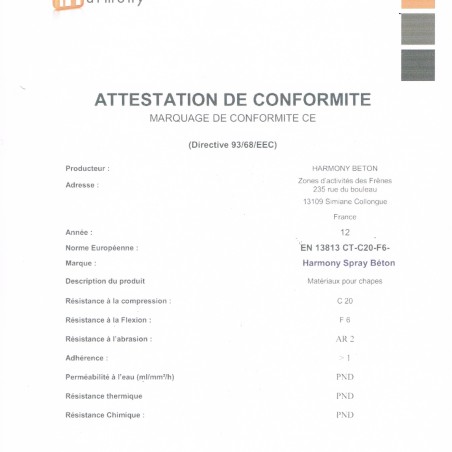

Compression strength: 20 N/mm2 after 28 days

Bending strength: 6 N/mm2 after 28 days

Dosage: 20 kg + 5 l resin = 7 - 8 m2 in two coats.

Storage: 6 months in unopened original packaging, stored in a dry and frost-free location.

Guarantee: Manufacturer’s liability

Compliant with standard NF EN 13813

Tools & Cleaning

Mixer, stainless steel smoother, gloves, spray gun.

Clean tools in water after use.

Preparation

The base surface must be resistant, sound, solid, clean, dry and free of humidity.

Use Harmony Neutral Agent or Harmony Degreaser for any cleaning required (to remove grease, oil etc).

Whatever the base surface, it is essential that the Harmony Primer range should be used, in order to prevent any resurgence of humidity or excessively rapid drying of mortar, and to enhance adhesion to the base surface.

On a porous base surface use Harmony Primer, and on an impervious base surface use Harmony Primer Plus.

On a wet base surface, such as a shower, sink, basin or, more generally, any porous surface (plaster, timber, syporex, BA 13 etc.) which is in regular contact with water and has not been sealed beforehand, Harmony Epoxy Primer should be used.

For more information, see the data sheets for primers.

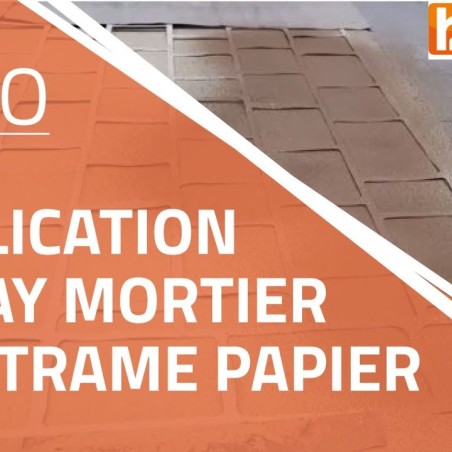

Application of sprayed concrete on a paper pattern

Harmony Sprayed Concrete is applied in two courses.

The 1st course is used to create the colour of joints in the patterned concrete.

The 2nd course gives the required colour of the motif in the pattern concerned (stone, slabs, etc.).

1. Mix one 25 kg bag with 5 litres of resin using an electric mixer, until a uniform mix is achieved. 1 litre of water may be added, if required. Pour the resulting mix into the reservoir of the PermaPro spray gun. Select the appropriate width of spray nozzle for the ground conditions.

2. Spray the product in a regular and uniform layer, ensuring that the entire surface is covered. After drying, position the paper pattern.

3. Mix one 25 kg bag with 5 litres of resin using an electric mixer, until a uniform mix is achieved. 1 litre of water may be added, if required.

Pour the resulting mix into the reservoir of the spray gun. Select a fine nozzle for the finishing course. 4. Spray the product in a regular and uniform layer, ensuring that the entire surface is covered.5. Leave to dry for 2 hours, then apply Harmony Premium Lacquer.For more information on Harmony Premium Lacquer, see data sheet.

Application of sprayed concrete for a waxed concrete effect

Harmony Sprayed Concrete is applied in two courses.

1. Mix one 25 kg bag with 5 litres of resin using an electric mixer, until a uniform mix is achieved. 1 litre of water may be added, if required. Pour the resulting mix into the reservoir of the PermaPro spray gun. Select the appropriate width of spray nozzle for the ground conditions.

2. Spray the product in a regular and uniform layer, ensuring that the entire surface is covered.

3. After drying, mix one 25 kg bag with 5 litres of resin using an electric mixer, until a uniform mix is achieved. Pour the resulting product into the reservoir of the spray gun. Select a fine nozzle for the finishing course.

4. Spray the product in a regular and uniform layer. Float the surface using the PermaPro Float to created waxed concrete effects. Use PermaPro studded boots to walk on the fresh surface.

5. Leave to dry for 2 hours, and apply Harmony Premium Lacquer.For more information on Harmony Premium Lacquer, see the data sheet.

Payment and delivery

Payment

We guarantee a secure payment by

Delivery

- Shipped within 48 hours After reception of payment. . Period for carriage between 2 and 4 days

- Delivery to the following countries

France, Belgium, Luxembourg, Germany, Austria, Poland. - For Corsica, the DOM/TOM and other destinations in Europe, please contact us so that we can assess the shipping costs

Customer Service

You can contact us

- via chat : at the bottom right

- via telephone : 04 42 20 10 09

from Monday to Wednesday from 8:00 a.m. to 8:00 p.m.

from Tuesday to Friday from 8:00 a.m. to 12:00 a.m. - via email : At the following address

contact@harmony-beton.com

Features

| Particle size | 0 to 0.4 mm |

|---|---|

| Consumption | 20 kg + 5 L of resin for 7 to 9 m² in 2 layers |

| Compression | 20 Npa |

| Bending | 6 Npa |

| Cleaning | Water |

| Compliant | NF EN 13813 |

| Conservation | 6 months in its original packaging, unopened and stored in a dry and frost-free |

| Warranty | RC manufacturer |

Product instructions

Reviews

Related products

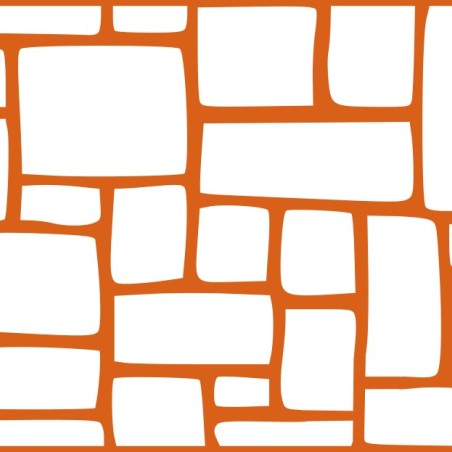

Concrete stencil - brick finish

Concrete stencil - paving finish

Concrete stencil - stone finish

You may also like

Concrete stencil - paving finish